Hi Everyone,

I just watched Taylor’s latest video of his gearbox teardown and suspension arm replacement.

It appears there was a breakage that occurred (after many kilometers of successful travel!):

What i’m curious about is this: based on Taylor’s verbal description of the failure mode, it seemed like crack formation was present before there was impact with a rock, and the impact simply accelerated the crack propagation.

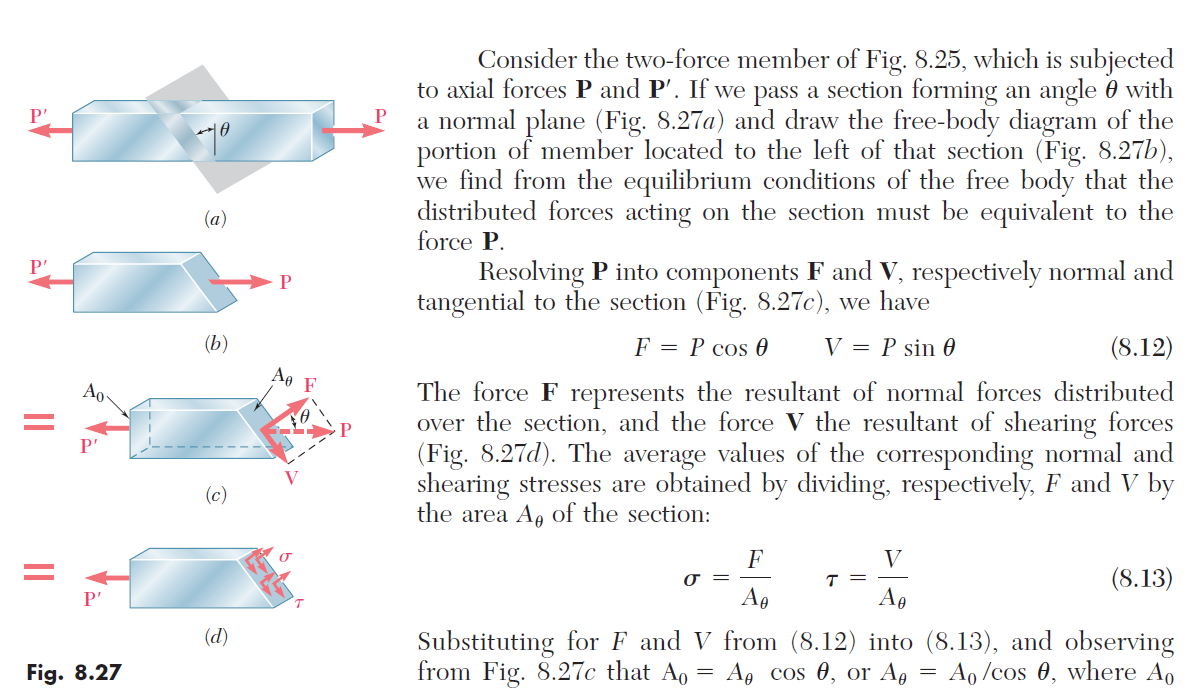

I’m not very familiar with 3D printing modes of manufacturing, but it occurs to me that from my Statics & Strength of Materials class (101) that in a simple model of an axially-loaded beam, the greatest stress occurs in the diagonal plane… which is very similar to what the video screenshot shows:

It also occurs to me that 3D Printing as a manufacturing process, intrinsically produces very ANisotropic material (the Young’s Modulus, e.t.c can vary depending on orientation under consideration). I also came across this brief web-article that details someone’s test of this idea: http://www.sparxeng.com/blog/mechanical/3d-print-orientation-effect-part-strength

Perhaps future design iterations should have notes for the 3D printing orientation? Not sure if I’m over-thinking this

Cheers,

Kai